Thermal paste is vital to your PC build, ensuring your CPU’s optimal function. When you’re out shopping for a new thermal paste, Customers usually aim for the one with the highest numbers, but there is a dark and hidden truth behind it. Sadly, these advertised numbers on thermal conductivity are never real.

Users need to be more cautious when they’re purchasing thermal paste and looking at the thermal conductivity and thermal resistance numbers. They’re false and misleading. Brands also tend not to disclose their lab testing to explain how they have achieved these numbers. Higher thermal-conductivity numbers are not always the ‘Best’, as we have done tons of reviews, and we can assure you that these marketing numbers shouldn’t be taken seriously.

How Do Thermal Pastes Work?

Well, a thermal paste’s job is to fill the microscopic gaps between the CPU and the heatsink, but multiple factors could influence its performance, such as the application method you’re using; the most commonly used methods are Cross Method, Pea-Sized and the spread-method.

Also, it depends on the mounting pressure of your heatsink to the CPU IHS if the force is applied enough to spread the thermal paste across the die and fill the microscopic gaps.

Thermal paste performance also depends on the paste’s quality, which is mainly thermal conductivity and thermal resistance. The lower the thermal-resistance numbers, the better, and the higher the thermal conductivity, the better the performance. We’ll explain below how much they matter.

Misleading Branding! Thermal Conductivity & Thermal Resistance

Let me break down the two key aspects of a thermal paste and how they can be misled.

Thermal Conductivity

Thermal Conductivity is calculated in (W/m·K); it refers to how effectively the thermal paste can transfer heat between the two surfaces, e.g., between CPU IHS (Integrated Heat Spreader) and the heatsink However, higher thermal conductivity numbers in the paste suggest better thermal performance, but here is a catch: these advertised numbers can be false. They should not be taken seriously because the thermal conductivity numbers solely would not tell us anything.

Higher ”Advertised” thermal conductivity numbers would not always result in better performance; it’s misleading for the brands to put these numbers to confuse the buyers.

In reality, thermal pastes have a thermal conductivity of 1 to 4 W/mK in real-world scenarios based on the thickness or layer of the application. Several brands, such as Arctic and Thermal Grizzly, have stopped advertising the thermal conductivity numbers, as the thermal-conductivity number could vary depending on the contact pressure, how hot the CPU is, how thick the application is, and the temperatures.

The thermal paste thickness is measured in micrometers (µm); the optimal values are 25–50 µm when cured or compressed. In electronics, we call it ”Bond line thickness” BLT in short, it refers to the thickness of thermal-paste between the two components (e.g., CPU and Heatsink); if the BLT is thin, it could reduce the thermal resistance; if the BLT is too thick or viscous, the layers may shrink or crack during the curing. But, how the brands have figured out the thermal conductivity and advertised them at what layer thickness is also very important, which they do not mention.

So, using too much application on the CPU, or less, can change the thickness, affecting the thermal-conductivity numbers. So, you should remember that these advertised thermal conductivity numbers are NEVER ACCURATE!

Thermal Resistance

Just like thermal conductivity, brands tend to mislead consumers about the thermal resistance values as well; if you do not know what thermal resistance is, thermal resistance is a measure of how well the paste transfers heat effectively to the heatsink depending on how thick the layer is, the denser the layer is, the more complex the transfer of heat would be, the lower thermal resistance is always preferable. Several factors could affect the paste’s thermal resistance, such as the contact pressure, the paste’s material, and the application thickness and temperatures.

The thermal resistance is measured in °C/W. If the paste is too viscous, just like the Thermal Right TFX or TF9, the thermal resistance wouldn’t be in the acceptable range as they have the problem with the minimum layer thickness; with the standard contact pressure, they cannot be compressed easily due to their large particle size in the fillers. As we have said, multiple factors can influence thermal resistance. These marketing values should not be taken seriously as they are not adequately documented besides the advertised values, which would mislead the customers.

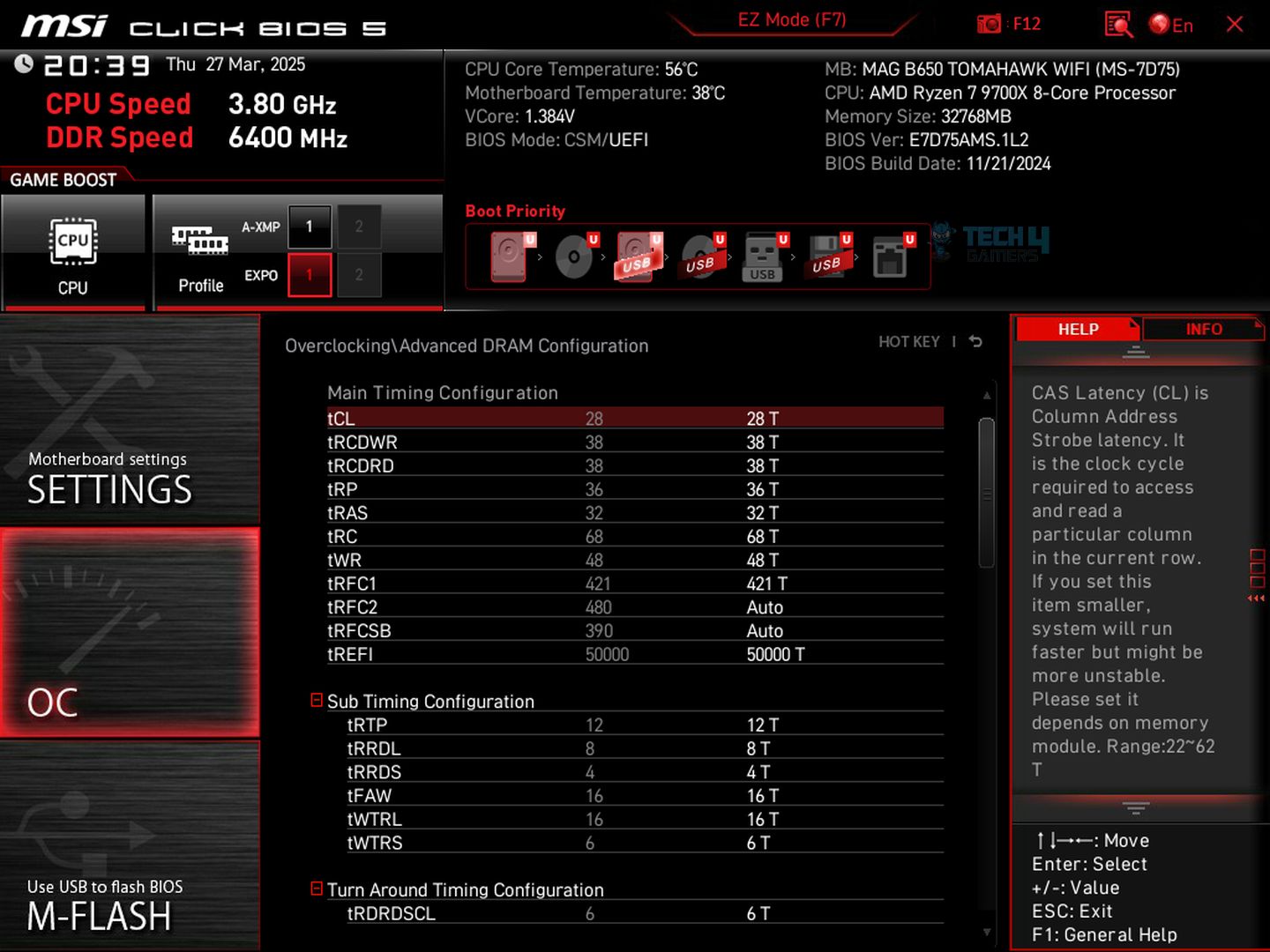

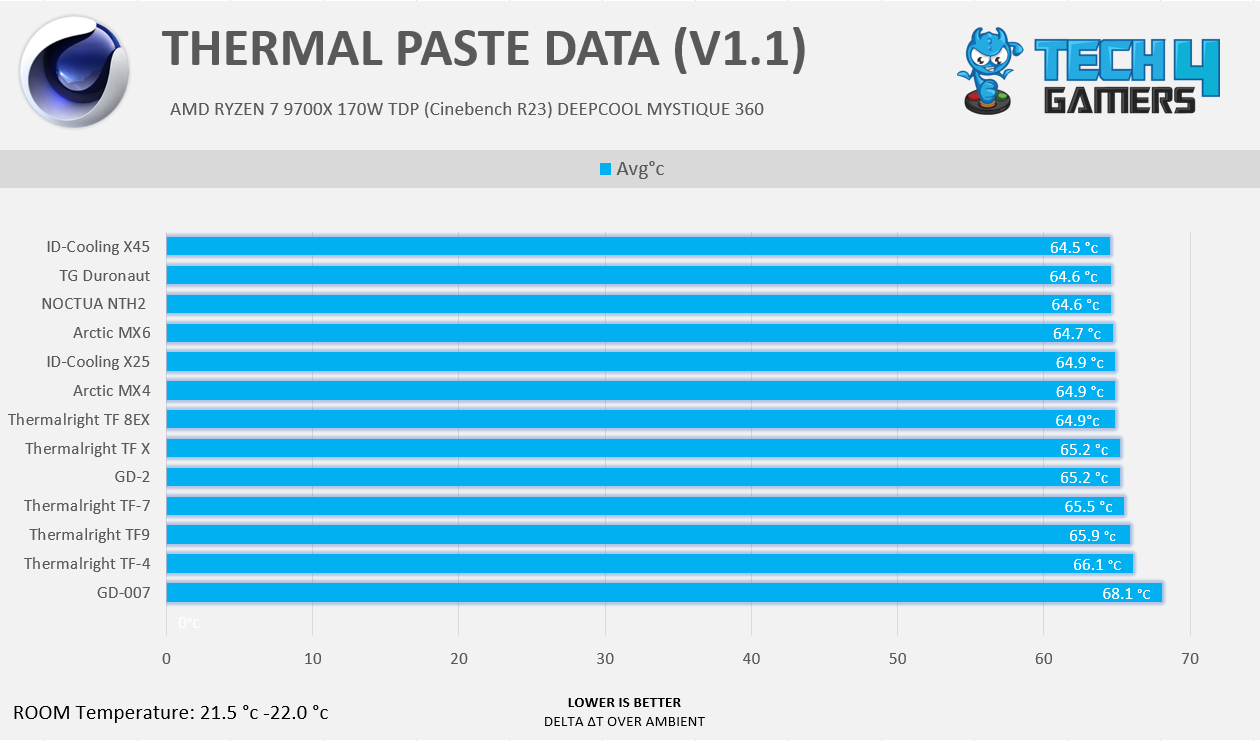

We’ve Tested 12 Thermal Pastes To Put Things To Light:

We have tested different varieties of thermal-pastes in the charts, including the most selling ones as Arctic MX4, and Arctic MX5, and some are from Thermalrights, ThermalGrizzly, and ID-Cooling.

These charts are the accurate representation of, whether the ‘higher-thermal-conductivity marketed’ performs the best, and the answer is no. For example, The Thermalright TFX has a conductivity of 14.3W/M-k, and thermal resistance is 0.28 (℃·cm²/W) yet it performs identically to ID-Cooling X25 which has the (Advertised) thermal conductivity of 10.5 W/m-K and the (Advertised) Thermal Resistance of 0.50cm3/W, while the highest numbers would have performed the better here but it’s not the case.

ID-Cooling is also advertising the false-misleading numbers, on what basis and condition and methodology they have performed these numbers are unknown.

What Is The Pump-Out Effect?

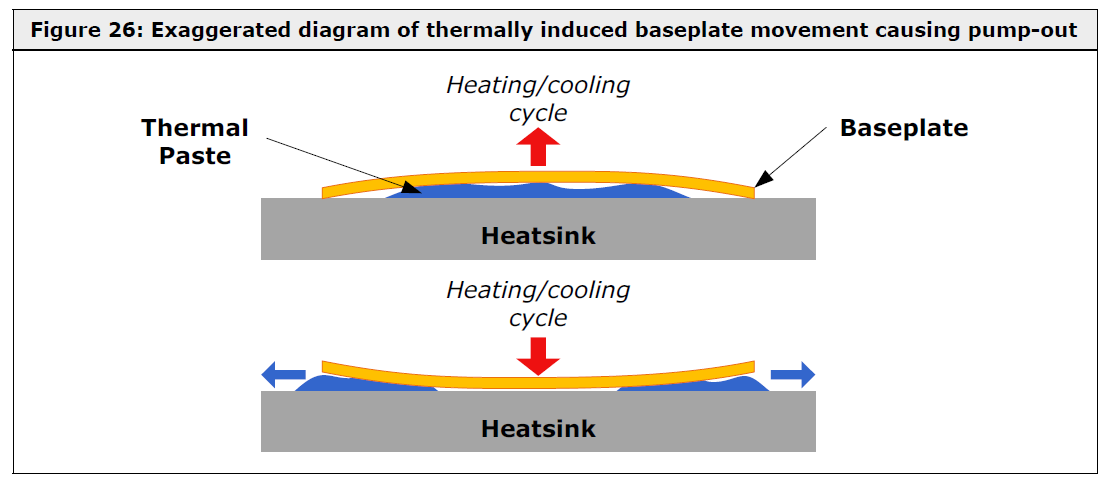

The pump-out effect is a common issue with CPUs and GPUs. Over time, the thermal paste between the chip and the heatsink gets slowly pushed out due to repeated heating and cooling cycles. When your CPU or GPU is under load, the components in the thermal paste expand. As this happens again and again, the paste gradually shifts and moves toward the edges of the contact area.

Over time, thermal paste loses its ability to conduct heat effectively, which can lead to overheating. As the paste heats up and its components expand, it becomes less thick and more runny, eventually breaking down or even evaporating. A less viscous paste would always pump out faster than the ones which are higher viscous.

How Do I Choose The Right Thermal Paste (CPU)

For the performance numbers, you can check our reviews of Thermalright, ID-Cooling X45, and ThermalGrizzly Duronaut, in the reviews we have tested up to 12 therma pastes and talked a lot about their durability. Of course, you can also look at the performance graph above.

Other than that, there are several things that you need to keep in mind, and on what component you’re applying the thermal-paste. If you’re applying on a CPU or a GPU, you should always aim for the right balance which is durability and performance, and don’t fall into marketing numbers.

Thicker, more viscous thermal pastes usually need a longer burn-in period and can sometimes have higher thermal resistance, which isn’t ideal. On the other hand, thinner pastes may perform better at first with lower thermal resistance and higher thermal conductivity. However, at high temperatures, they can break down or “bleed” more quickly, and their performance often gets worse over time due to the pump-out effect

Ease of application also matters here. Some people prefer the spread method, where they apply a thin layer of paste directly onto the IHS and spread it evenly—mainly for peace of mind. However, thicker, more viscous pastes can be harder to spread using this method.

For Graphics Cards, Is Using A Thermal Paste A Good Idea?

While it’s generally a good idea to replace the thermal paste on your graphics card after several years of use, graphics cards have become power-hungry these days; the RTX 5090 can reach up to 600W, and the thermal paste on the GPU would bleed faster than it’s on the CPU as CPU’s tend not to get hot as the graphics card. These days, GPUs have two temperature sensors on the die: the GPU temperature, which takes the reading from the die, and the other Hotspot Temperatures.

Well, GPU Hotspot Temperature refers to the highest achieved temperature on the GPU die, measured at the hottest sensor location; the hotspot temperatures could be a good indicator to tell that the thermal paste is bleeding or in the process of ‘Pump-out’.

Vendors nowadays are applying PTM pads on the GPU die to make sure it’s longevity. What happens when you apply the thermal paste on the GPU die is that the GPU die remains cooler and provides good hotspot temperatures; after several heat cycles or weeks/months of use, the paste starts to disappear from the GPU, which can cause the hotspot temperatures to rise.

What is PCM Or PTM?

PTM stands for Phase-Change Thermal Material, and PCM stands for Phase-Change Material. These are types of thermal paste or TIM (thermal interface material) that come in the form of solid foam pads. They look similar to the thermal pads used on GPU memory and power phases.

Still, the difference between them is that the thermal pads always remain solid and don’t melt. In contrast, PCM or PTM turns to liquid at certain temperatures at 45-50°C Degrees and spreads across the die, filling the microgaps on the die, and when they’re at the cooled state, it automatically transitions to the solid state just like the thermal pad.

These phase-change materials are difficult to apply but are easily durable and could last up to 4 years. I highly recommend our users get the PTM material when they decide to change the thermal interface material on the GPU.

Thank you! Please share your positive feedback. 🔋

How could we improve this post? Please Help us. 😔

I’m Usman Sheikh, a Senior Hardware Reviewer at Tech4Gamers with over a decade of experience in the tech industry. My journey began in 2014 as a senior administrator for Pakistan’s largest gaming community forum. Passionate about PCs and hardware, I specialize in testing and reviewing components like graphics cards, CPU coolers, and motherboards, while also sharing insights on overclocking and system optimization.

Threads

Threads