- Elon Musk is moving toward the goal of establishing chip production in the US.

- A new PCB centre is already operating in Texas, and the FOPLP factory is expected to be operational by 2026.

- Ultimately, the CEO of X aims to become self-sufficient and produce chips at a time when others may suffer due to shortages.

We’re seeing how the CEO of X, Tesla, and SpaceX, among other firms, is discreetly working towards a goal that, two years ago, would have appeared impossible.

Elon Musk is establishing an entire chip production and packaging chain in the United States, including everything from PCBs to FOPLP and a future wafer facility capable of meeting demand from Tesla, SpaceX, and Starlink.

As reported by DigiTimes, Elon is developing his own TSMC, LAM Research, and Tokyo Electron, suited to his requirements and built to function independently in critical situations. The change appears rational when we consider capacity lock-ins, supply problems, and Musk’s failed battle with TSMC to gain manufacturing priority.

This is really going to happen, and the initiative starts with two physical pillars. The new PCB centre in Texas is already operational. Second, the FOPLP (Fan-Out Panel-Level Packaging) factory has begun machinery installation and plans to start limited production in the third quarter of 2026.

SpaceX’s goal is to combine chip packaging for satellites, cut costs, and maintain complete control over Starlink components. Before the production line starts, the ecosystem is powered by RF and power management chips ordered from STMicro and Innolux, but these purchases will be reduced as internal production increases through 2027.

In other words, in just over a year and a half, Elon Musk’s companies will begin pulling production orders from their partners and manufacturing them themselves, in secret, under their terms and designs, from start to finish.

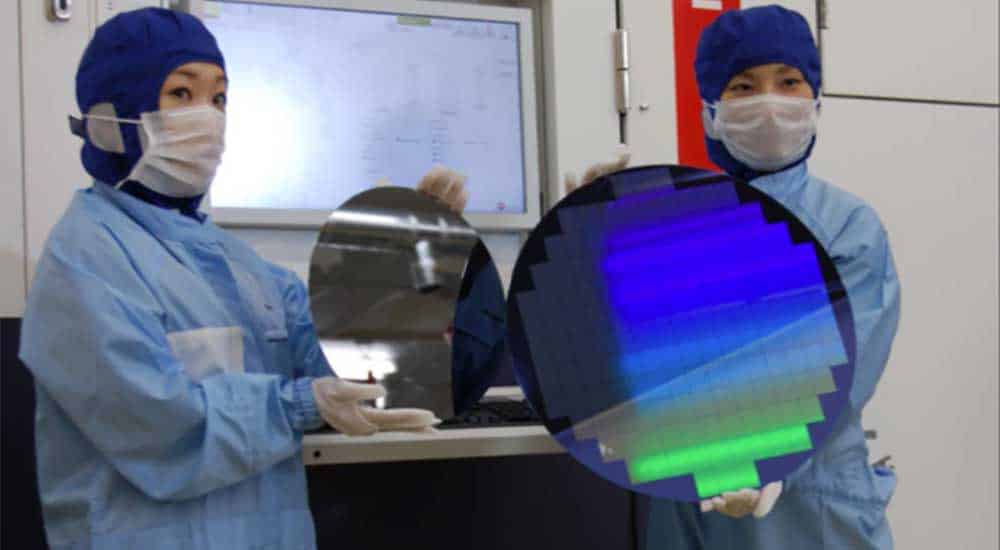

Also, Musk aims to build a wafer mega-factory capable of producing 100,000 wafers per month and eventually 1,000,000. Although it may not compete with TSMC in advanced nodes, it is capable of producing 14-nanometer and smaller circuits, complementing Musk’s vision for robotics, autonomous driving, and satellite networks.

Tesla and SpaceX may use this level of technology to avoid geopolitical concerns and capacity limits in Taiwan and South Korea, aligning with their operational aims. The tech tycoon has recruited personnel from Intel, TSMC, and Samsung, and his words indicate that his mind is totally focused on chips.

The idea of a self-sufficient supply chain meshes with his aim to develop his business without relying on vendors who may fail in supplying during the future peaks in demand for AI.

Thank you! Please share your positive feedback. 🔋

How could we improve this post? Please Help us. 😔

[Editor-in-Chief]

Sajjad Hussain is the Founder and Editor-in-Chief of Tech4Gamers.com. Apart from the Tech and Gaming scene, Sajjad is a Seasonal banker who has delivered multi-million dollar projects as an IT Project Manager and works as a freelancer to provide professional services to corporate giants and emerging startups in the IT space.

Majored in Computer Science

13+ years of Experience as a PC Hardware Reviewer.

8+ years of Experience as an IT Project Manager in the Corporate Sector.

Certified in Google IT Support Specialization.

Admin of PPG, the largest local Community of gamers with 130k+ members.

Sajjad is a passionate and knowledgeable individual with many skills and experience in the tech industry and the gaming community. He is committed to providing honest, in-depth product reviews and analysis and building and maintaining a strong gaming community.